Inquiry Sheet Required Items

形状

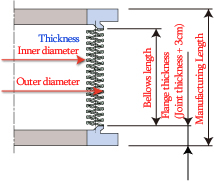

| Bellows ID | Inside Diameter of Bellows(The figure below) |

|---|---|

| Bellows OD | Outside Diameter of Bellows(The figure below) |

| Flange Thickness | Total thickness for Flange with bellows welding lip (3mm) (The figure below) |

| Face-to-Face | Dimension Between edge faces |

We may ask for change bellows size due to our cycle life assurance. Please specify the condition of ID and OD of bellows.

Ex. Shaft is installed inside the bellows. (Because shaft OD is 20mm, bellows ID should be 22mm.)

Ex. Installed housing outside of the bellows. (Bellows OD should be 45mm due to avoid interference.)

Material and Environmental Condition

If using corrosive gas inside or outside the weld bellows, please choose to use corrosion resistant material

Pressure condition

| Inside of Bellows Outside of Bellows |

Please select either Vacuum/Atmospheric Pressure/Pressurization/Fluctuating Pressure. |

|---|

Notes for Pressurization

If you select Pressurization please specify gauge pressure

Notes for Fluctuating Pressure

If pressure condition is not constant (e.g. repeating vacuum and atmospheric pressure), please send the pressure fluctuation pattern. Our engineer designs the bellows with expected maximum load.

Operating condition

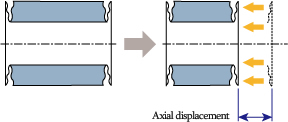

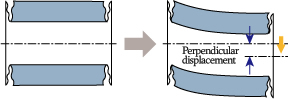

As for type of displacement, please see the description below. If there is displacement caused by a equipment operation etc., please specify.

Axial displacement refers to the length difference before and after deforming the bellows in axial direction by external mechanical load.

Both end surfaces of bellows is made parallel. Perpendicular displacement refers to the length difference keeping the end surfaces parallel.

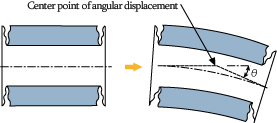

Angle displacement refers to the angle difference of axis before and after being applied some load. In this case, the bellows could deform in axial and perpendicular direction so the combination of axial and perpendicular displacement must be considered.

Temperature condition

Please specify operating temperature (normal/max).

We will select the material and consider the stress load in the high temperature environment.

Required Cycle Life

Please specify the required cycle life that you need us to assure (number of cycles).

Mirapro designs with considering metal fatigue based on the number of repeated cycles. If thereare multiple operating patterns, the cumulative damage evaluation will be performed in considering of the combinations. So if operating range or pressure condition etc. differ between normal operation and maintenance, please inform us the details.

Spring Constant

Since welded bellows has a spring element, it generates some counterforce. Generally, Mirapro offers spring constant as a result of designs that meet bellows cycle life requirement and ask our customer to reflect it in the equipment design. However, please inform us if the spring constant is one of design constrains.

Installed Direction

Please specify installed direction (vertical, horizontal or others)

When installing horizontally, please make sure to specify it because it is necessary to consider the self-weight deflection.

Note for the other specifications

| Operating Speed | When the operation speed is fast, the amount of local expansion and contraction of the bellows increases due to the inertial force compared to when the operation is slow, and the cycle life is relatively reduced. Please inform us the operating speed in case of using for valve etc., or operating with high-speed to improve the takt time. |

|---|---|

| Shaft | If more precise evaluation is required, we may ask for more information on the bellows operating pattern. Please specify diameter and placement information if a shaft is installed inside the bellows. The bellows may buckle depending on the size and length of the bellows, so we may offer using a shaft (inside/outside) or pantograph structure in order to secure enough lifetime cycle life. |

Information for inquiring

Relationship between Bellows Length and Cycle Life

Mirapro optimizes wave profile/thickness/size (inside diameter/outside diameter) of diaphragm based on the conditions provided from customer to avoid the risk of destruction by metal fatigue.

In order to reduce stress, reduction of displacement amount per bellows convolution and improvement of cross-section strength etc. are needed, so we increase the number of convolutions and change the thickness of bellows diaphragm. We may offer a length that could meet required cycle life through meetings with customer.

Bellows Buckling

When a bellows buckles, the extremely decreases. Therefore, if a shaft is installed inside the bellows, we may offer adding an intermediate ring guided by the shaft. Also, if a shaft cannot be installed inside the bellows, we may offer adding guide mechanism outside the bellows.

Bellows is mounted vertically in the right side picture, however, if a bellows is installed horizontally, the bellows gets easier to buckle due to its own weight, so we need the designation about installed direction.

When bellows is short no concern, but if the bellows becomes long, the deformation of the bellows will be delayed with respect to the behavior of the flange and it will not be uniform, resulting in uneven expansion and contraction in the axial direction of the bellows. In this case, we may propose a pantograph structure.

Bellows Material

The factors that determine the material for bellows are durability (life), corrosion resistance and heat resistance. The materials used for welded bellows and its characteristics are as shown below. AM350 is supplied to the market as spring steel, having a high strength. Since it has magnetic property and its corrosion resistance is little lower, its application is limited. However, when long cycle life is required, in many cases where AM350 is selected.

| Corrosion resistance | Heat resistance | Cycle Life | Magnetic Property | |

| SUS316L | Normal | Can be used | Normal | Normal |

| AM350 | Relatively low | Can be used | Good | Yes |

| HASTELLOY C-22 | Good | Good | Normal | No |

※As for the other materials, please contact us for the details.