Next-generation flywheels, the project we are participating in, has been selected as one of ICEF’s Top 10 Innovative Technology of 2015

It is selected by ICEF members based on three perspectives: GHG emissions reduction potential, Innovativeness, and feasibility.

This technology has been selected as one of the technologies to solve above technical issues, and it has been selected as a remarkable technology that has begun to realize it.

the next generation flywheel Energy storage system has been published in the following page.

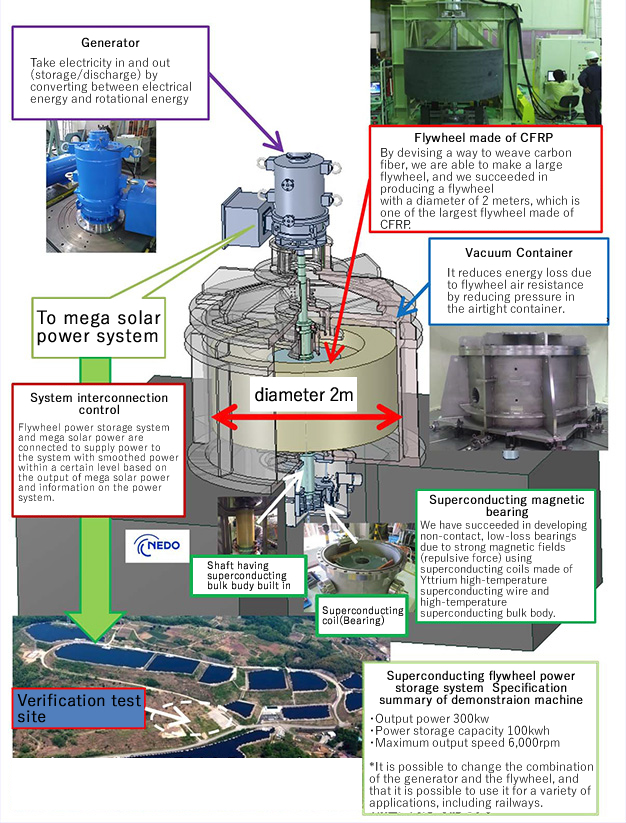

World’s largest Superconducting Flywheel Energy Storage System test machine is developed

World’s largest Superconducting Flywheel Energy Storage System test machine is developed(Development of a test ingress for the world’s largest superconducting flywheel storage system)

Separate window will be opened for linked URL.

Outline of selection of next generation flywheel energy storage system

Superconducting Flywheel Energy Storage System Test machine is developed.

Superconducting Flywheel Energy Storage System Test machine is developed.Organization:Railway Technical Research Institute, Kubotek Corporation, Furukawa Electric Co., Ltd., Mirapro Co., Ltd., Public Enterprise Bureau of Yamanashi Prefecture (Japan)

Period:April/2015

The Railway Technical Research Institute (RTRI) has developed a superconducting flywheel energy storage system, as a next-generation power storage system, with support by NEDO. This is the world’s first superconducting magnetic bearing which uses superconducting material both for its rotor and stator, and is capable of supporting heavy weight, although it is a compact-sized system. The flywheel energy storage system is capable of storing energy in the form of kinetic energy by rotating a flywheel, and converting the rotating energy again to electricity. RTRI developed a superconducting magnetic bearing composed of a high-temperature superconducting coil and high-temperature superconducting bulk for the developed system. These enable the flywheel to be levitated by the superconducting magnetic bearing without contact. It is a very practical system, which enables stable fluctuating power generation such as PV over a long period. It has been connected to a solar power system and power grid of Tokyo Electric Power Company in Yamanashi Prefecture.

Comments

Compared to hydro pumping, superconducting Flywheel Power Storage System will improve storage efficiency from 70% to 85%. With assumption that 1.2milion kW of flywheels will be deployed by 2040, the improvement by Superconducting Flywheel would bring about a 400 million kWh reduction of electricity consumption (around 200 thousand t-CO2) a year.

Innovativeness

The project is innovative in that it is the first demonstration to use superconducting material both for rotor and bearing.

Feasibility

The project demonstrates the technological feasibility of applying a superconducting material both for rotor and bearing.

Global warming prevention technology selected from Japan

●Toyota Motor Cooperation :the first commercial FCV, MIRAI

●Mazda:The most fuel efficient diesel car ever –the Demio

●MHI Vestas: Power production technology by a wind turbine