Vacuum Insulation Technology

Vacuum insulation technology has become very familiar as in vacuum insulation bottles are sold in the market these days and widely used in various fields.

However, vacuum insulation technology has hardly been utilized in Semiconductor equipment which is required cutting-edge technology.

That is because not only insulation accuracy is required, but also strict quality assurances which is high cleanliness, quality control and clearly providing product lifetimes are required.

As the technology for semiconductor becomes more sophisticated and demand increases, advanced thermal control is required depending on productivity or product specification and new insulation function become necessary.

We “MIRAPRO” has been accumulating fundamental data and production “know-how” while at the same time, performing internal evaluation test and grasp the characteristic of thermal transfer in almost same condition as actual products. That enhances prediction accuracy and contribute to minimize lead time of equipment development.

It enables us to design and produce products that meet difficult requests from equipment manufacturers.

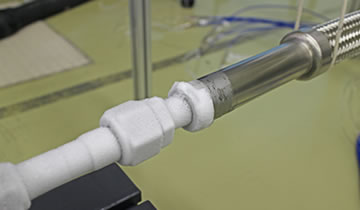

Low temperature insulation test

Lightweight double layer pipe and

liquid nitrogen storage container

| Developments | Vacuum insulation pipe for cryogenic and high temperature Low temperature transportation container Thin-walled vacuum pipe with low heat capacity |

|---|---|

| Existing Customer | Semiconductor manufacturing equipment manufacturers for deposition, etching process etc. Pharmaceutical equipment manufacturers that require low-temperature transportation Automotive parts manufacturers as applications for heat damage countermeasures |